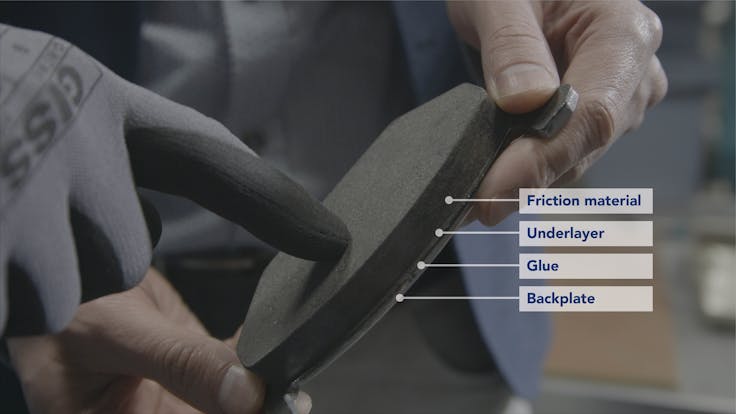

Most brake pads of cars and commercial vehicles have an underlayer between the friction material and steel backplate. This underlayer ensures good bonding strength with the backplate, dampens vibration and noise generated in the braking system, and gives a thermal and moisture barrier. And, depending on the raw materials used in the underlayer, it may save costs.

Despite these key functions, the brake pad underlayer is often undervalued and underappreciated. There has been relatively little work on its development, but its properties are critical to the performance and safety of the whole brake system.

The underlayer is glued to the backplate using an adhesive (see Figure), in most cases phenolic based.